Numax - Wear Plates

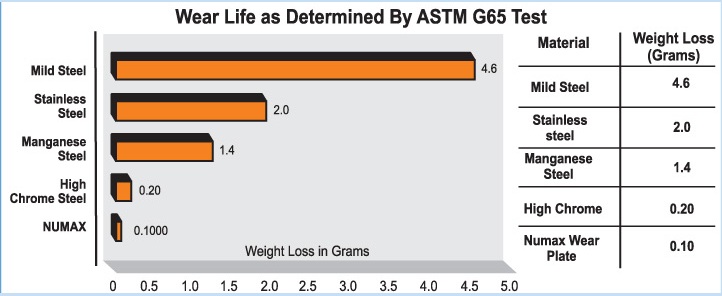

The wear solution for Indian core – sector industry presents the modular concept of wear protection using NWIPL Wear Resistant Plates. These wear plates are constituted of steel backed superlative wear resistant cladding. Manufacturing of these plates by a specialized Square wave technology for fusion bonding process offers significant advantages in terms of lowest dilution levels, highest concentration of carbides and superlative resistance to abrasion. NWIPL Wear Resistant Plates users in a new era of wear protection for design & maintenance engineers over traditional wear protection using Manganese steel Ni-hard, Hi chrome, Heat treated, Stainless steel or Hard facing by welding.

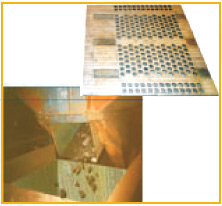

NUMAX Wear Plates

Cut to Size

From 100X100mm Up to 2800X 1250 or as per client requirement.

Square holes from 15X15 mm,

round holes from 15 mm,

Tear Shaped holes from 6/8X50 mm.

NUMAX Standard Wear Resistant - Plates

Size (in mm) : As per requirement.

Thickness (in mm) : 5+3, 6+4, 8+4, 10+4

12+4, 8+7, 10+7, 12+7, 16+7 and as

per customers requirement.

Base plate : IS 2062, St.37.2, St. 52, 13 CrMo 44, 1.4825 and as per customers requirement.

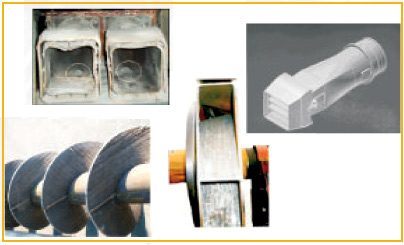

Fabricated components : As per Industrial requirements.

NUMAX Wear Plates Grades

NUMAX 784

NUMAX 721 M

NUMAX 784 PR

NUMAX 711

NUMAX 712

NUMAX 713 PR

NUMAX 713 SPL

As per customer specification

Applications

Application for Cement Industry

- Primary Crusher Liners, Secondary Crusher Liners.

- Cyclone for Cement Plant, Elbow joint for Duct, Row mill inlet chute, Body liner, Armor ring, Separators vanes, Cone, Fan Casing Liner, Louver ring.

- Raw material Slurry Pipe & Elbows. Clinker Hoppers, Clinker hood liner.

- Finish Cement Piping & elbows, and all possible applications to combat wear.

Application for Power Industry

- Burner Tip, Screw Conveyor for coal feeding, Transition piece for coal hopper.

- Coal Crusher Liners, Coal handling chute liners, Pulverizer Classifier Cones.

- Ash Hopper Liners, I.D Fan Housing Liners and all possible applications to combat wear.

Application for Steel Industry

- Furnace part for sponge iron plant, Screen for sinter plant

- Iron ore inlet cone, Feed pipe for Ferro alloy

- Hopper and bell, all possible applications to combat wear

Applications for Mining and Opencast Mining

- Bucket Wheel Excavator

Buckets, Bucket blades, Bucket corners

- Mining Machines

Bucket chain excavators,

Single bucket excavators,

Dozer Components like Edges, End bits etc.

Wear life